The Micor MIG Pulse Series

Bid farewell to the transition arc. Welcome the MicorMIG.

The innovative Lorch pulse process allows low-spatter welding with MicorMIG Pulse series welding units. This saves time-consuming rework and prevents time loss from needless welding rod changes. The Lorch MicorMIG Pulse series sets new standards with its simple and effective transfer to a cutting-edge, steplessly adjustable welding system.

The fully flexible, dynamic settings optimally adapt the arc to your needs. Its welding properties and an excellent price-performance ratio combine to turn the MicorMIG Pulse series the ideal entry-level candidate for pulse welding.

Overview of the advantages of the MicorMIG Pulse series.

Future-proof technology in a perfectly practical housing. Keep your system safe all around with the impact protection and gas-cylinder safety device. The MicorMIG also stands out with its inner values as it is packed with cutting-edge technical features and interior illumination.

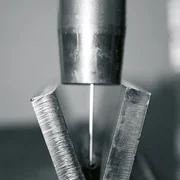

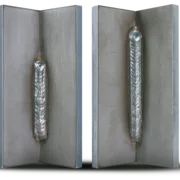

Low-spatter pulse welding.

The stable pulsed arc that can be controlled very well saves rework and time for other tasks. The pulsed process warrants low-spatter welding without any time-consuming rework across the entire synergy characteristic curve.

MicorBoost-technology for perfect welding results.

The innovative and patented Micorboost technology maximises power and the voltage reserve in the arc, optimising welding properties for all sheet metal as well as medium and heavy steel work. This results in outstanding welding results on steel, stainless steel, and aluminium.

EN1090 conformity + NFC technology.

Easily weld EN1090 compliantly thanks to the WPS booklet. Save some time- and cost-intensive individual tests of your welding results. The booklet contains independently certified welding instructions for all the relevant standard welding procedures. The MicorMIG series also keeps your parameter sets conveniently available via an NFC job card.

Future-proof by upgrade capacity.

Always just the functions you need: The NFC function makes the MicorMIG Pulse series welding units fully upgradeable, allowing you to subsequently install additional welding processes, welding programmes, and functions to facilitate work with NFC cards at any time, offline and without needing any external support.

Perfect quality assurance with the authorisation concept.

NFC technology allows setting up of a personalised authorisation system for welding system operation. The MicorMIG allows use of NFC authorisation to ensure that only specific welders are allowed to adjust the corresponding parameters. A timed lock for the end of the working day additionally prevents unauthorised work on the device.

Outstanding price-performance ratio.

The MicorMIG Pulse offers an easy switch to a fully adjustable welding system. Profit from the optimal welding properties of the MicorMIG Pulse at an excellent price-performance ratio.

Energy efficiency by technology.

The Lorch MicorMIG Pulse combines robust performance with efficient inverter technology and a stand-by function. This reduces costs while achieving perfect welding results. Transformers are a thing of the past.

Mastering difficult welding tasks with the MicorMIG: the MIG-MAG speed processes.

Mechtech Engineers, a renowned name in the welding industry, has revolutionized welding technology with their cutting-edge products. One of their most sought-after innovations is the MicorMig Pulse Series, which has set new standards for automatic MIG welding machines. In this article, we’ll delve into the key features and advantages of the MicorMig Pulse Series and how it has become the go-to choice for welding professionals worldwide.

The MicorMig Pulse Series:

The MicorMig Pulse Series by Mechtech Engineers is a game-changer in the world of automatic MIG welding machines. Designed to meet the diverse needs of welding applications, these machines offer unmatched precision, efficiency, and user-friendliness. Whether you’re a seasoned welding expert or a novice in the field, the MicorMig Pulse Series sets a new benchmark in welding technology.

Key Features:

Pulse Welding Technology:

The MicorMig Pulse Series utilizes advanced pulse welding technology that ensures optimal arc control and weld bead appearance. This feature helps reduce spatter, minimize distortion, and achieve superior weld quality.

High Performance:

With the MicorMig500 Lorch Welding Machine as the flagship model in this series, users can experience exceptional welding performance. The machine’s robust build and cutting-edge components allow for continuous operation and consistent results even in challenging welding projects.

User-friendly Interface:

Mechtech Engineers understands the importance of ease-of-use. The MicorMig Pulse Series comes equipped with an intuitive control panel, making it easy for operators to adjust welding parameters and achieve precise welds effortlessly.

Versatility:

Whether you’re working on thin sheets or thick metal plates, the MicorMig Pulse Series sets a new standard in versatility. It can handle a wide range of materials, including steel, stainless steel, aluminum, and more, making it an ideal choice for various welding applications.

Advantages of Choosing MicorMig Pulse Series Sets from Mechtech Engineers:

Enhanced Efficiency:

The MicorMig Pulse Series optimizes welding processes, leading to increased productivity and reduced downtime. Its innovative features significantly improve welding speed without compromising on weld quality.

Cost-effectiveness:

While automatic MIG welding machines can be an investment, the MicorMig Pulse Series offers excellent value for money. Its exceptional performance and durability ensure long-term reliability, resulting in cost savings in the long run.

Technical Support:

As a trusted supplier, Mechtech Engineers provides excellent technical support and customer service. Whether it’s installation, training, or maintenance, their team of experts is always ready to assist.

Conclusion:

In conclusion, if you’re in the market for a high-quality automatic MIG welding machine, the MicorMig Pulse Series by Mechtech Engineers should be at the top of your list. Its cutting-edge technology, user-friendly interface, and exceptional performance make it a game-changer in the welding industry. Experience the future of welding with the MicorMig Pulse Series and take your welding projects to new heights of precision and efficiency. Contact your nearest Mig welding machine supplier today to learn more about the MicorMig Pulse Series by Mechtech Engineers.